Energy Equipment

- Products

- Energy Equipment

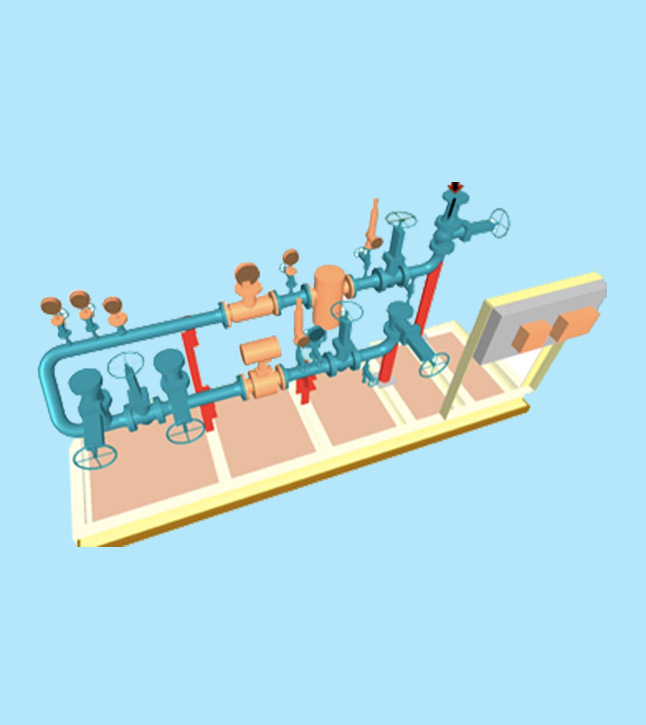

Chemical Injection Skid

Chemical Injection Systems can be used across the Oil & Gas industry, from Upstream application to Midstream and Downstream use. These skids are used to inject a precise and accurate amount of chemical into the system with the required back pressure, continuously or at intervals.

Specification:

- We specialize in Design and Fabrication of Transportable/Permanent, Skid Mounted Chemical Injection Systems.

- These systems are built to customer requirement and in accordance with international design codes/standards.

- Pump selection, material of construction compatibility with chemical. Use of proven system component, 3D modelling to check case of operation and maintenance etc. are some of the key design features of our system.

We Offer:

- Single point or multipoint Injection Systems.

- Discharge rates from 0.1 to 300 LPH and discharge pressures from 0.1 to 10,000 psi.

Pig Launchers & Receivers

Bliss America is happy to offer Pig Launchers & Receivers as part of our portfolio, as an engineered solution to pipeline pigging. Install this product on each end of your pipeline to launch a “pig” that will inspect and clean. Also known as a “Scraper”, the pig scrapes the inside of the pipe to allow the fluids to run through unobstructed.

Specification:

- Quick opening end closures provided.

- Includes pig signalers and pressure safety valves.

- Suitable for installation on all pipelines.

- Designed to the relevant API & ASME certifications.

- Variety of materials available, though pigs are typically made of stainless steel or carbon steel.

- Corrosion-resistant coatings available if required.

Surge Relief Systems

A Surge Relief System is designed to alleviate pressure in a pipeline that could cause damage to your skid components, equipment or employees if it remains unchecked. The pressure is caused when the velocity of your fluid changes quickly or suddenly, due to unforeseen circumstances such as an emergency shut down, having a pump trip, etc.

Specification:

- Surge Relief Systems are typically used for the following applications:

- Liquid Pipelines

- Storage Tanks

- Product Loading/Unloading Terminals

- Refineries

Metering Systems

A metering skid is a fully mounted unit on which several assemblies can be installed. With Custody Transfer being the primary use of such a skid, we are proud to announce that our Energy Division is capable of customizing our metering skids to suit your Custody Transfer needs for both liquids and gas.

Specification:

- Features:

- Compact and well-engineered layout to facilitate easy access to valve

- PLC-based control panels for unattended operation

- Electrical components

- Instrumentation

- Valves

- Interconnecting piping

- Pre-conditioning of fluid before flow measurement

- Major Components:

- Multiple Meters/Meter Runs

- Flow Computers

- Quality measurement: Fluid Energy Contents - chromatograph

- Master Meter Calibrations

- Supporting Automation & Communication Systems

- Filtration & Conditioning

- Indirect Heating (optional at the outlet)

- Pressure Regulation & Flow Control (at the outlet)

- Sampling Systems

- Adherence to international standards such as ISO, API, etc.

- Ensured compliance to local measurement regulations.

2/3 Phase Separator System/Skids

Primary equipment for Separation of Liquid & Gas (Two Phase) or Oil, Water & Gas (Three Phase) from Oil Well Stream.

Specification:

- Primary equipment for Separation of Liquid & Gas (Two Phase) or Oil, Water & Gas (Three Phase) from Oil Well Stream.

- Designed & Manufactured as per API 12J.

- Internal Inlet Impingement Baffles, Wave Baffles, Flow Straightening Baffles, Weirs, Mist Eliminators & Vortex Breakers provided for effective Separations.

- Equipment adequately designed to allow sufficient retention period.

- Controls & Instrumentation provided to accurately measure the Gas, Oil & Water Flow rates, regulate the Pressure and Monitor the levels of Oil, Water in the Separator.

- Automated Liquid (Oil & Water) removal system provided.

- Large Size / Pressure Range.

- Compact, Skid Mounted System can also be provided.

Indirect Water Bath Heater

An indirect water bath heater is used primarily in the oil & gas industry, to heat process fluids or gases evenly. The temperature of the process fluid is raised by placing it in a utility bath, rather than heating it directly.

Specification:

- Gas Fired Indirect Water Bath Heaters designed in full compliance to API 12K specifications.

- Natural Draft Burners, directly mounted on Fire Tube. Forced Draft Burners also provided as per requirement.

- Precise temperature control of Water Bath.

- Equipment adequately designed to allow sufficient retention period.

- Removable Single or Twin Fire Tube Design.

- Removable Heating Coil for ease of maintenance.

- Burners System complete with Pilot, Main Burner, Gas Train, Spark Igniter with Transformer provided.

- Flame Arrestors at Burners Air Intake and Stack Top provided.

- Large Heating capacity upto 5 Million K.Cal/Hr.

Gas Conditioning and Regulating Systems

Gas conditioning is a process in which the quality of gas in an operation is improved by filtering out contaminates and regulating its temperature and pressure. This avoids premature combustion, pipe and nozzle plugging and equipment erosion. Gas conditioning systems are primarily used to treat engine fuel gases and combustion turbine gases, as well as to process and treat wellhead gas prior to distribution. It increases the longevity of the turbine, wellhead or pipeline.

Specification:

- Ensures supply of Dry and Dust Free Gas.

- Generally it comprises of a 1 × 100% Knockout Drum & 2 × 100% Filter Separators together with Indirect Water Bath Heater (as per service requirement) complete with Interconnecting Piping, Valves, Instrumentations, Electrical and PLC based Control Panels for unattended & smooth operation.

- Separation and Removal of Liquid from the Gas Stream.

- Compact, well-engineered skid mounted layout to facilitate easy access to all Valves, Instruments & Filter Elements.

- Condensate Tanks & Vent Stack also provided.

- Stainless Steel piping used downstream of Filter Separation System to ensure contaminant free pure gas.

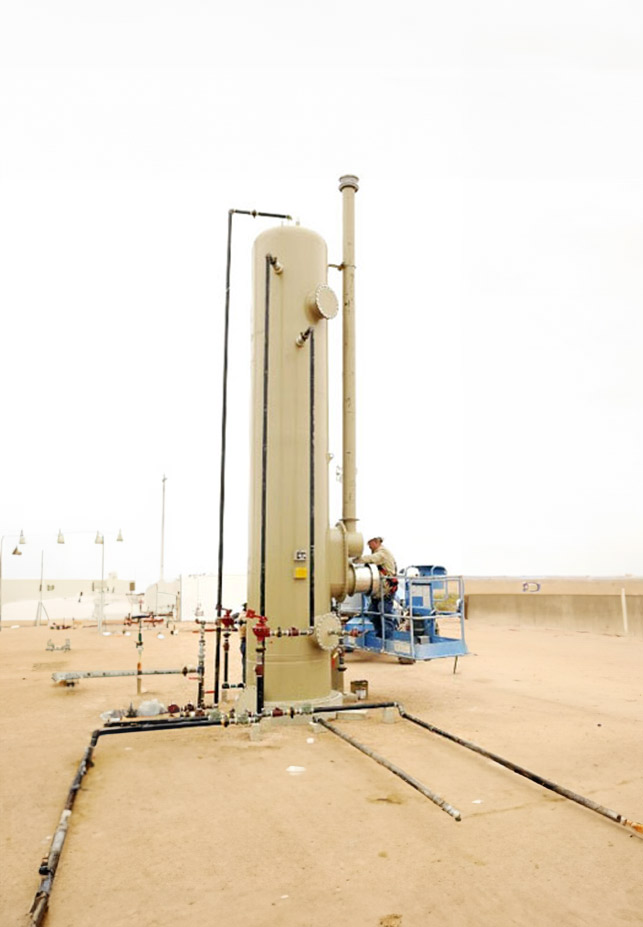

Filter Separators/Dry Gas Filters

For removal of liquid / solid particles down to 1 micron with 99. 9% efficiency.

Specification:

- For removal of liquid / solid particles down to 1 micron with 99.9% efficiency.

- Horizontal / Vertical design.

- High performance, proven make, coalescing type glass fiber elements used in primary section.

- Secondary section provided with efficient impingement separators or mist eliminators to remove coalesced liquid.

- Compact, well engineered skid mounted layout to facilitate easy access to all Valves, Instruments & Filter Elements.

- In horizontal filter separator down comers from primary and secondary sections pass liquid to sump to prevent re-entry.

- Large liquid collection volumes.

- Equipment provided with quick opening closures for quick access to filter elements.

- Provision for automated liquid level monitoring & liquid removal.

Hydrocarbon Storage Tank

Design, engineering, procurement and fabrication of above ground steel storage tanks with complete in-house design facility for floating, cone & dome roof tanks as per API 650.

Specification:

- Design, engineering, procurement and fabrication of above ground steel storage tanks with complete in-house design facility for floating, cone & dome roof tanks as per API 650.

- Supply includes tank protection systems like fire protection, rim seal fire protection, and cathodic protection systems.

- Procurement & supply of tank accessories like flame arrestors, side entry mixers, radar gauges, level instruments, heating coils & other instruments as per engineering requirement.

- Technical support & assistance provided by trained personnel during erection & commissioning.

Heater Treater

Gas separation section designed to "thin film" entering emulsion for quick gas break out.

Overview

Bliss Heater Treaters are meticulously crafted to seamlessly execute the oil-gas separation process, eliminate free water, provide heating, facilitate settling, and conduct the crude oil washing procedure—all housed within a single, space-efficient unit.

This skid-mounted heater treater comes fully equipped with valves, instruments, and accessories, guaranteeing secure and dependable unattended operation.

Specification:

- Gas separation section designed to "thin film" entering emulsion for quick gas break out.

- SImmersed downcomer piping from gas separation section to emulsion spreader serves as an effective heat exchanger to preheat incoming emulsion and cool the clean oil.

- Deep Freewater Knockout sections below the firebox provides isolation and draw off free water, thereby avoiding unnecessary heating of water and conserving fuel.

- Controls & Instrumentation provided to accurately measure the Gas, Oil & Water Flow rates, regulate the Pressure and Monitor the levels of Oil, Water in the Separator.

- Quick adjustable outside water siphon provides easy interface control over a wide range of water and oil specific gravities.

- Adequate surge volume in the clean oil section relieves heading overload in gas separation section eliminating the possibility of liquid carry-over with the gas.

- High capacity firebox furnishes abundant heat and quick response to thermostatically controlled demand.

Rim Seal Fire Protection System

Designed to automatically detect and extinguish fire at the infancy stage.

Specification:

- Designed to automatically detect and extinguish fire at the infancy stage.

- Operates on the principle of arresting chain reaction.

- Precise temperature control of Water Bath.

- Non-electrically operated, Remote surveillance facility.

- No water supply needed.

- Modular design with option of Foam Based or clean gas based.

- Unlimited shelf life of CF3I.

- System is mounted on the roof of the tank and can be installed while the tank is in service.

- Global technology.

- Suitable for lightning prone areas.

- System Complies to NFPA 2001, EPA standards.

- Instrumentation Complies to NFPA 2001, Ex 112 GEX ia II T5 standards.

Topping Unit

Topping units primarily consist of crude distillation which produces first cut of Naphtha, Kerosene, Diesel and Residue Distillates.

Specification:

- Topping units primarily consist of crude distillation which produces first cut of Naphtha, Kerosene, Diesel and Residue Distillates

- Quality and quantity of this first cut product depends on assay of incoming crude

- The incoming crude is first taken into a desalter, then into a heater to heat it to 1,292 °F (700 °C)

- It is then fed into the distillation column where the top part extracts Gas, Naphtha and Kerosene, and the downcomers collect Diesel and Residues

- These are primarily built into modular capacities of 3,000 barrels per day – 20,000 barrels per day

- These are useful for remotely located oil fields

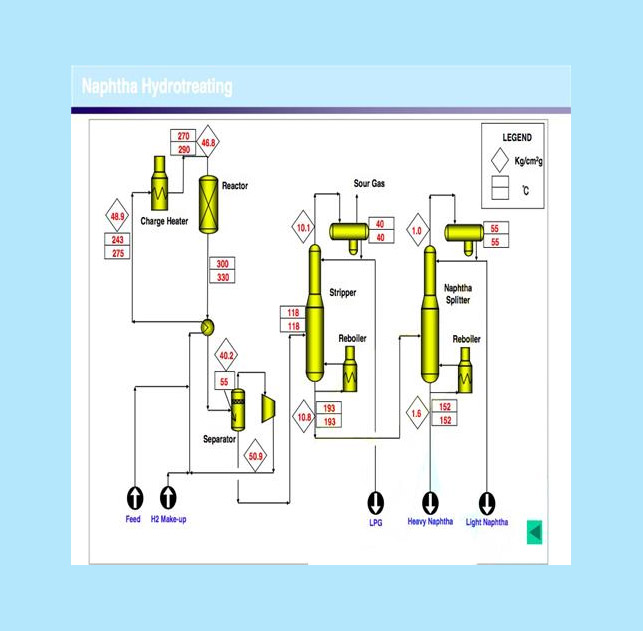

Hydrotreater & Reformer Packages

Hydrotreater is primarily used to remove sulphur, nitrogen and metals from the feed received after the distillation.

Specification:

- Hydrotreater is primarily used to remove sulphur, nitrogen and metals from the feed received after the distillation

- Hydrotreater is used for Kerosene Hydrotreating (KHT), Diesel Hydrotreating (DHT), Naphtha Hydrotreating (NHT)

- Hydrotreater is used to increase octane number (ron :102) by reforming

- Fixed bed reformers are used primarily to upgrade Naphtha to Gasoline

- Continuous catalyst regeneration in order to maintain catalyst activity

Loading/Unloading Stations:

Loading/Unloading Stations primarily consist of pumping stations and metering stations, and then taken into loading gantries.

Specification:

- Loading/Unloading Stations primarily consist of pumping stations and metering stations, and then taken into loading gantries

- Loading Arms are installing in the loading gantries to rail or load tankers

- Scope can include Product Tanks and Utilities

- Loading gantries are designed and numbers selected depending on the volumes of product loading

- This entire process of pumping, metering and loading is interlocked for an automatic operation and shutdown