Quality & Testing Facility

- Manufacturing

- Quality & Testing Facility

Quality & Testing Facility:

At Bliss America, we adhere to a rigorous quality testing procedure, ensuring that all our products not only meet international codes and standards but also align with the unique requirements of our discerning customers and specific project needs. We extend an open invitation to our valued customers, encouraging them to visit and/or conduct audits at our state-of-the-art plant, fostering transparency and confidence in our manufacturing processes. Our arsenal of cutting-edge quality testing machines encompasses a comprehensive array of tools, each playing a pivotal role in guaranteeing the excellence of our offerings. These include, but are not limited to, precision pressure testing equipment to assess resilience under varying pressures, dimensional measurement tools for meticulous size and tolerance verification, and non-destructive testing (NDT) equipment like ultrasonic and magnetic particle testing for thorough material inspection without causing harm. Furthermore, our commitment to quality is underscored by the use of material analysis instruments, temperature and environmental testing chambers, vibration testing equipment, and corrosion testing apparatus. These tools collectively ensure that our products not only meet stringent material standards but also excel in real-world operating conditions.

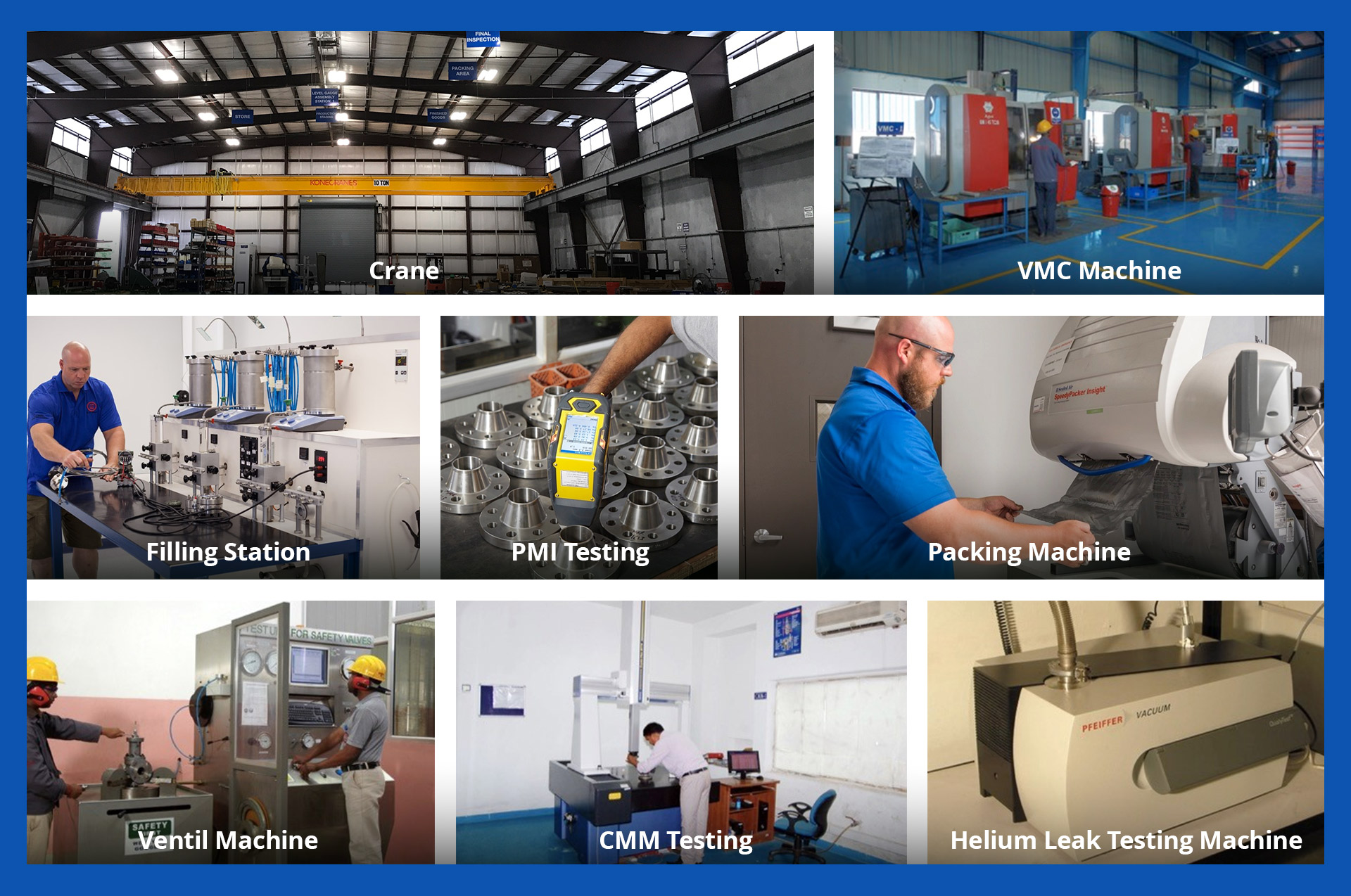

1. Crane

The crane is primarily used during production and assembly of skids in our Energy Equipment Division.

2. VMC Machine

Bliss VMC Machines are used to cut metal to precise dimensions for all our products.

3. Filling Station

Our facility includes a filling station that has the capability of filling up to 10,000 seals per year.

4. PMI Testing

We have in-house Positive Material Identification to determine the quality and chemical composition of the raw materials we use.

5. Packing Machine

Bliss America uses Speedypacker Insight® to package our products.

6. Ventil Machine

We use Ventil Machines for testing and adjusting the set pressure, seat tightness and general performance with Gas or Liquid test systems, at a range of 0 – 15,000 PSI.

7. CMM Testing

A Coordinate Measuring Machine is used to measure physical geometrical characteristics of an object. It ensures the quality of all the dimensions.

8. Helium Leak Testing Machine

Bliss America uses Helium Leak Testing to locate and measure potential leaks in a product or system.